THE ULTIMATE PRECAST PRODUCTION & CURING ENVIRONMENT!

Chameleon Retractable Enclosures are the ultimate solution for precast concrete production and curing. They allow you to carefully control temperature and humidity in order to create optimal conditions for producing/curing products while keeping employees dry, comfortable and safe.

Return on Investment

Expand production capacity with building-like protection

Increase revenues by shortening your production & curing cycle

Extend your production year-round in both cold and hot weather

Raise product quality in both appearance and strength

Increase work efficiency by working under-cover in a shaded and precipitation-free environment

Benefits

Prevents Product Defects and Shrinkage Cracking By:

Blocking the Wind

Blocking the Sun

Preventing Temperature Gradients Within Product

Allowing Air to Free-circulate

Buffering Temperature Changes

Containing Humidity

Increase Production Efficiency By:

Providing Protection from Extreme Cold

Provide a heated work environment before and after pouring

Protecting Employees from Precipitation

Allow employees to work even in extreme rainfall

Proving Shade from Sun

Allow employees to work in the shade; Prevent forms from getting hot; form liners from UV

Being Manually Operable

Operate enclosure using people-power rather than high cost equipment.

Allowing Easier Plant Reconfiguration

Much easier to relocate and scale than traditional tarps and kilns.

Features

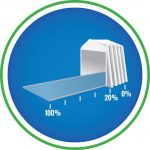

Retracts to approx. 20% its overall length

High strength structure designed to your application and climate

Durable, flame-retardant (NFPA 701), UV-protected PVC shell

Vapor-proof seams are Hi-Frequency Welded (Not Sewn)

Operable in windy conditions without tie-downs.

Clear-span doors at each end

Easy to install

Easy to repair

Options

Factory pre-assembly available for low enclosures

Curtain and wall separators to provide cells

Removable rail configurations for forklift side access

Services

Consultation

Installation Supervision

Turn-key Installation

Applications

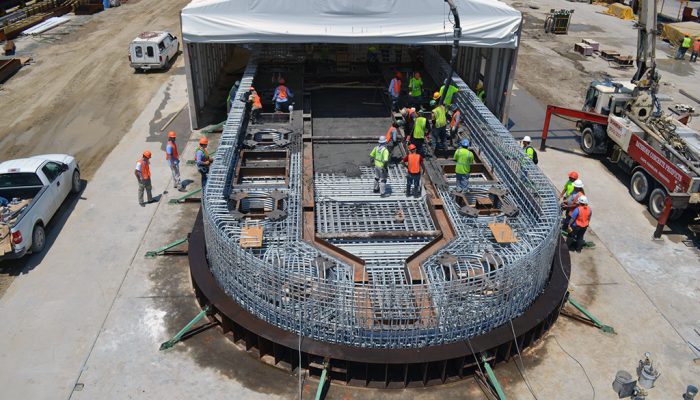

OUTDOOR PRECAST PRODUCTION & CURING

Chameleon Retractable Enclosures make the Cold and Hot Weather Concreting consistent:

INDOOR PRECAST PRODUCTION & CURING

AGGREGATE STORAGE SOLUTIONS

Prior to mixing, keep aggregate:

Moisture controlled

Free of ice/snow chunks

Temperature controlled

OSHA SILICA – DUST CONTAINMENT & FILTRATION SOLUTIONS

Benefits

Meets the OSHA Silica Rule with ease

Allows control and monitoring of silica levels

Limits exposure to employees creating dust

FAQ

How can I get a quote?

We should know the following in order to provide you with a precise proposal:

Interior (length x width x height) clearances.

Location of the project to appropriately calculate appropriate wind and snow loads.

Site limitations:

Overhead clearance restrictions.

Site plans to understand the traffic situation around you forms (a simple sketch or description is completely acceptable)

Do you have any ideas of the Return on Investment of your product?

Here are a few tips for calculating your ROI:

- Most of our precast clients have experienced a decrease of 25% in boiler fuel costs.

- Our enclosures require approximately 2 people per 50-75ft of length to extend and retract. A 50ft long curing blanket normally requires a team of 6 or more workers plus a crane/lift operator.

- Never miss a pour! What is the value of what you are covering? Pour and cure in hot and cold weather conditions without failing. As long as your employees can work, your Chameleon retractable will be ready to work as well.

How long do these enclosure last?

The structures are designed to last indefinitely if well maintained and operated manually for precast applications:

- We build the structures out of aluminum and use stainless steel fasteners

- We use stainless steel sealed bearings in all of our wheels

- The fabric shell has a treatment that provides protection against UV rays and needs to be replaced between 5-10 years. Longer lasting PVDF fabrics are also available.

If the fabric shell is damaged, do we need to replace it?

In most situations, the tarp can be patched as easily as patching a bicycle tube. Glue and fabric can be purchased at most local awning shops. Heat guns can also be used for larger tears.

Testimonials

“[The sales team] was a great help in the whole process, from getting the buildings designed to their final commissioning. Chameleon’s service was timely, and the product is high quality, all of the parts went together without incident on site. Thank you for all of your hard work, excellent product, and service.”

William S. Harris, PE, Plant Manager, Bayshore Concrete Products

“[The Technical Sales Rep] did an excellent job work with our employees and teaching them how to install and work with your product. He was very professional and we are very pleased that we spent the money to have him come here.”

Peter Schuster, Precast General Manager, Lafarge Winnipeg Precast Division

“Our fuel costs to produce the live steam were enormous, and we also lost a lot of treated water from our steam boiler system. We installed a Chameleon canopy system a week ago and are finding that we have turned down the steam pressure by about 25%.”

JIM MELNECHENKO, PLANT MANAGER CON-FORCE STRUCTURES

“Chameleon worked closely with us during the concept and design phases and provided knowledgeable, hands-on site assistance during installation. I would not hesitate to recommend Chameleon Innovations for any firm seeking retractable tarp solutions.”

RANDY PRIMEAU, CET, LEED AP MANAGER PRESTRESSED SYSTEMS INC.