Chameleon Retractable Enclosures: The Ultimate Engineering Control

Many believe that Personal Protective Equipment (aka PPE) will be the solution to meeting the OSHA Silica Rule but it is not that easy or inexpensive.

Operations/hazards that have been identified as ones that will likely be above OSHA’s acceptable silica exposure limits:

- Grinding and cutting of precast.

- Media blasting.

- Cleaning forms with compressed air.

- Dust stirred-up around the plant by vehicles and material handling equipment.

- And more… Silica dust is everywhere in a precast plant due to unenclosed dust creation processes.

Our initial impression is that PPE is the inexpensive and simple solution. If only using PPE for your employees, you will need to:

- Monitor silica exposure levels throughout your property and provide PPE for all employees exposed to silica dust.

- Maintain records of the exposure and training of all employees exposed.

- Perform routine medical exams and maintain history on all employees exposed. Medical exams are costly and even more so for employers in rural locations.

- Ensure that masks are fit-tested and all employees conform to facial hair requirements in order for masks to fit.

- Ensure all employees are consistently and constantly trained on task, hazard and work practice engineering control.

- Fines will be substantial for precasters whose employees fail to follow these requirements.

If PPE is not the ultimate solution, then what is?

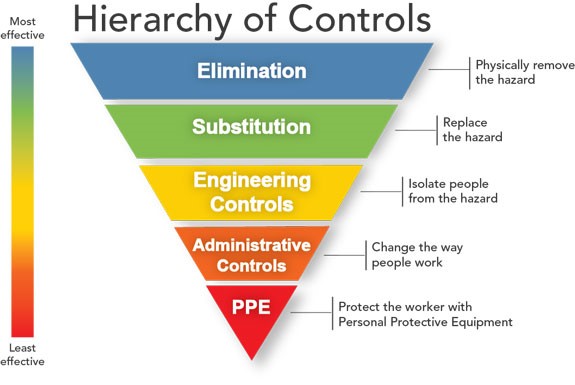

Ultimately, the best solution is to ELIMINATE or SUBSTITUTE typical practices like grinding, cutting and media blasting but that is not typically an option in precast production.

Ultimate Solution: Engineering Controls – Isolate Employees from The Hazard

Silica dust is found throughout precast plants due to unenclosed dust creation processes. Chameleon Retractable Enclosures are a containment solution (engineering control) that will allow you to only expose a limited number of employees to silica dust since permanent enclosure solutions (ex: tents) do not efficiently work with cranes or concrete delivery systems.

The Ultimate Engineering Control: Chameleon Retractable Enclosures

- Provide unrestricted 360-degree access to a work area, when retracted, allowing unhindered access to the precast product via crane, forklift etc.

- Provide an environment where silica levels can be contained/controlled and easily monitored.

- Protect production employees and forms/product from the weather – hot sun, wind, freezing temperatures, rain, etc. What is hard for your employees, is typically hard on precast production efficiency.

- Engineered to your local wind and snow load requirements.

- Chameleon supplies and retrofits various dust collector solutions.

The Bright Side for Precast Manufacturers:

The silica rule will only be harder for cast-in-place contractors. This should give precasters a competitive edge:

- Precast concrete is manufactured in a factory and shipped to a construction site for assembly. That means all manufacturing processes creating dust occur at precast factories, not the job-site. You can apply engineering controls during manufacturing to capture dust in a factory where more costly engineering control solutions or time-penalizing job site segregation-of-operations will be required for those who cast-in-place on the job site.

- Most openings are formed/molded into precast pieces (an engineering control) rather than cut in cast-in-place job sites. This means the additional costly dust control requirements, from cutting openings at the job-site, are avoided by precasting.

- Precast concrete products are custom designed. You can adjust product layout and add reinforcing to minimize the amount of cutting required at the job-site.

- Precast has a short construction duration. Coordination of subcontractors to prevent silica dust contamination between trades is likely to become a real concern at the job-site. The short construction duration, when precast is used, means job-site crews create dust fewer days, thus affecting other job-site trades people less.

All-in-all, the silica rule will be a challenge for everyone in construction but there are solutions and more so for those in the precast industry. Be prepared. The purpose of this OSHA rule is to decrease silica dust that does result in the terminal illnesses of thousands of tradespeople in our industry yearly.

References:

- OSHA’s Final Rule to Protect Workers from Exposure to Respirable Crystalline Silica: https://www.osha.gov/silica/

- OSHA’s Proposed Crystalline Silica Rule: https://www.osha.gov/silica/factsheets/OSHA_FS-3683_Silica_Overview.html

- Precast and the New OSHA Silica Rule: https://www.wellsconcrete.com/blog/precast-new-osha-silica-rule/

- NPCA – OSHA Silica Rule: http://precast.org/wp-content/uploads/2016/08/OSHA-Silica-Rule-2016.pdf

- Prepare Early for OSHA’s Silica Exposure Regulation: http://precast.org/2016/07/prepare-early-oshas-silica-exposure-regulation/

- OSHA’s Crystalline Silica Rule: General Industry and Maritime: https://www.osha.gov/Publications/OSHA3682.pdf